Thrive Evolution Tech

Thrive Management Group is extremely proud and excited to have partnered with global bi-fuel experts GFS Corp and hose manufacturer Matex Hose. These strategic partnerships begin an exciting new chapter for Thrive, and has ultimately lead to the development of Thrive Evolution Tech – A business dedicated to the sale, service and support of industry leading technologies specific to the Thrive group of companies. Such strategic partnerships provide Thrive with the ability to pass along additional cost savings through innovation all while improving safety and reliability.

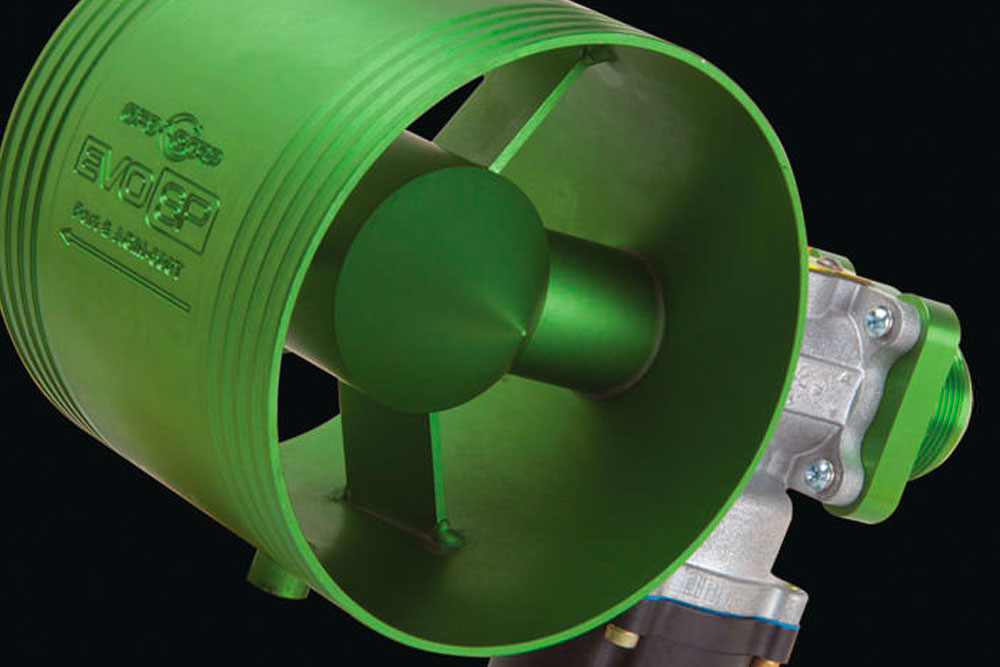

EVO-SP Bi-Fuel Technology

The EVO-SP system for stationary applications has changed the industry with its entirely new approach to bi-fuel controls by pro actively adjusting the gas supply instead of reacting to engine load. Now high gas substation rates are possible for dynamic load applications like those found in oil drilling and fracking, compressor applications and other demanding mechanical applications such as high volume water pumping.

Building on a powerful platform designed for the most demanding off-road applications GFS Corp applied lessons learned in converting dynamic, variable speed off-road engines to natural gas + diesel (NG+D®) operation in some of the world’s harshest, most demanding environments. The EVO-SP is proven and ready to meet the demands of the most challenging applications.

Smart and Powerful Controls with Advanced Engine Monitoring

Dynamic stationary applications require powerful and smart controls. The EVO-SP system has been optimized for precise and responsive control of natural gas fueling using a proprietary electronic control unit (ECU) coupled with a fast-acting, integrated mixer-throttle body. EVO-SP provides high resolution, dynamic mapping of natural gas and diesel mixtures across the engine load range using a 50 hertz / 50X per second control loop. This rapid control loop allows the EVO-SP system to safely and efficiently replace up to 70% of the engine’s diesel fuel requirement with natural gas without compromising engine response or power output. In the event of a fault or loss of natural gas supply, the EVO-SP® System seamlessly reverts the engine to 100% diesel operation without loss of power.

Installation, Maintenance and Repair

Thrive Evolution Tech’s factory certified technicians are ready to take on all installations. Thrive’s EVO specific service truck is fully equipped with the latest tools and technologies for make even the most difficult installations a possibility.

Dual Fuel Fleet

Thrive Fluid Management owns and operates several EVO-SP units within its pump and power generation fleet. This technology increases customer savings and drastically improves the equipment’s carbon footprint. In the right application this EVO-SP ready equipment has been proven to reduce diesel consumption by as much as 70%.

Applications

- Electric and Hydraulic Drilling Rigs

- Mobile Fracturing Pumps

- High Volume Water Pumps

- Irrigation

- Emergency Stand-By Power

- Prime Power

- Peak Shaving

- Load Sharing

- Co-Generation